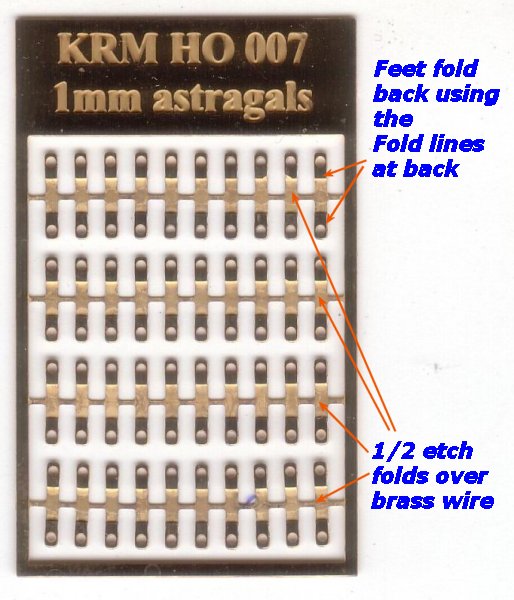

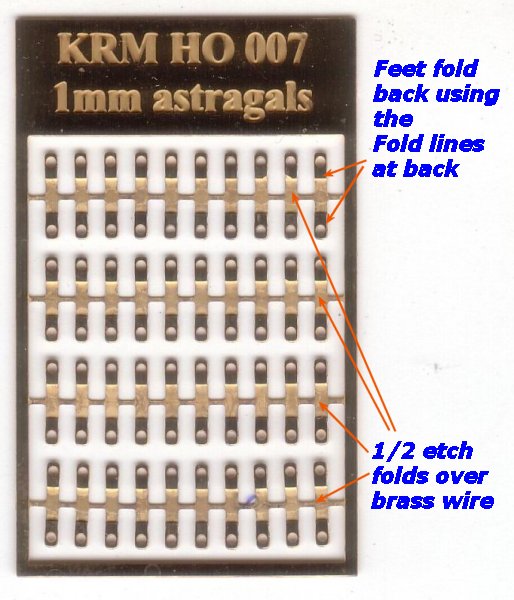

KRM HO 007

HO Astragal Kit to suit 1mm Brass Wire 3"-4" downpipe

Information Page

KRM HO 007

HO Astragal Kit to suit 1mm Brass Wire 3"-4" downpipe

Information Page

This kit is the start of a more comprehensive array of astragals to fit certain common wire sizes. This kit suites 1mm brass wire, ans is very easy to use, if not a little bit fiddly (but the effort is worth it).

Photos of some common uses of astragals, will be available shortly.

Step 1 - Tools & Equipment |

|

If there is one thing that I would like to impress upon you, it is the benefit of using quality tools to do your work; the end result of any job is plainly due to the use of good quality tools. And there is also a saving by using good tools, because they last longer, and therefore you do not need to replace them as often.

|

Step 2 - Preparing the Etch |

|

|

Step 3 - Preparing the Astragal |

|

by email or phone on 61 2 46772462 |

Keiran Ryan